- Pipe & Drain Jetting

- Leachate System Maintenance

- Pipeline Video Inspection

- Pipe Waterblast Descaling

- Pipe Laser Profiling

- Storm System Vacuum

- Lift Station Cleaning

- Waterblast Surf. Cleaning

- Pipe Locating

& Mapping - No-Dig Point Repairs

- Smoke Testing

- Flow Metering

- Trash Chute Cleaning

- Tube Bundle Cleaning

- Tank Cleaning

- Hydro-Excavation

- Pipe & Drain Jetting

- Leachate System Maintenance

- Pipeline Video Inspection

- Pipe Waterblast Descaling

- Pipe Laser Profiling

- Storm System Vacuum

- Lift Station Cleaning

- Waterblast Surf. Cleaning

- Pipe Locating

& Mapping - No-Dig Point Repairs

- Smoke Testing

- Flow Metering

- Trash Chute Cleaning

- Tube Bundle Cleaning

- Tank Cleaning

- Hydro-Excavation

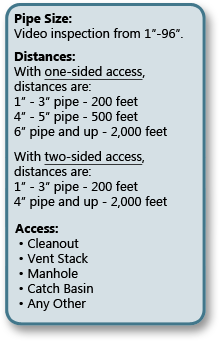

Pipeline Video Inspection

What is achieved- Pipe conditions and problems identified.

- Problem location precisely established.

- Facts can be presented in video format for third-party viewing.

- An informed decision can be made regarding remedial action.

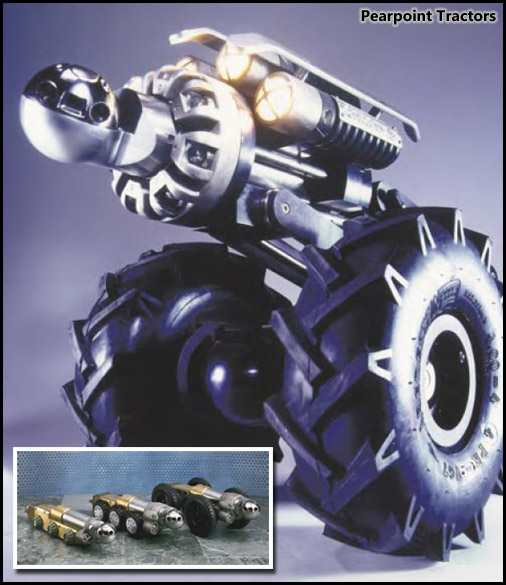

PEARPOINT state-of-the-art video inspection equipment:

- Pushrod systems

- Tractor-driven crawlers with inclinometers and/or laser profilers

-

Certified explosion proof

(Class I, Division I, Gas Groups C & D Compliant) - Elevator crawlers for larger pipes